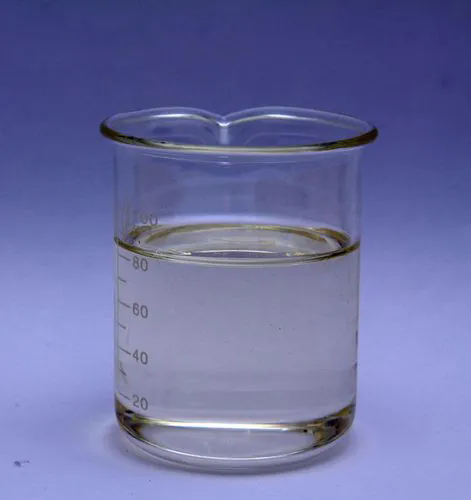

According to the specific construction environment and requirements, select the appropriate type of defoamer (such as silicone type, polyether type, etc.), and consider factors such as defoaming speed, defoaming performance, and compatibility with cement mortar. Meanwhile, environmental friendliness and cost-effectiveness are also

important considerations that cannot be ignored.

Before use, it should be thoroughly mixed to ensure that the defoamer is evenly dispersed in the cement mortar. During the construction process, the amount of defoamer can be adjusted according to the actual situation to achieve the best effect. At the same time, pay attention to the temperature and humidity of the construction

environment to avoid adverse effects on the defoaming effect.

English

English

Chinese

Chinese Vietnamese

Vietnamese

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT