In the production and application of water-based varnish, the generation of foam is a common problem, which not only affects the appearance quality of the paint, but also may lead to construction difficulties, poor drying and coating performance degradation. Therefore, the rational use of defoamers for water-based varnish has become the key to improving the quality of coatings. This article first outlines the basic concept of defoamers and provides a detailed classification of them.

Overview of defoamers

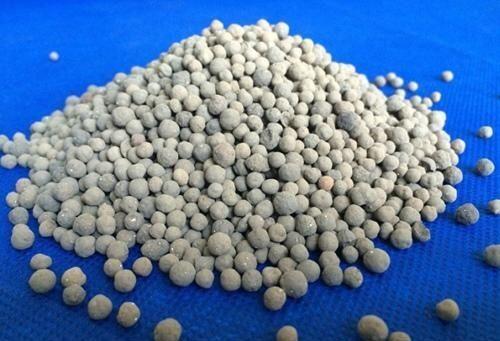

Defoamer 1825 defoamer is a chemical substance that can destroy or inhibit the formation and stability of foam in liquid. In water-based varnish system, defoamer can effectively control and eliminate foam by reducing surface tension, destroying the elasticity of foam film or accelerating the discharge of foam.

Classification of defoamers

Organosilicon defoamers: Known for their efficient defoaming ability and long-lasting anti foaming performance, they are widely used in the field of water-based coatings. The silicon oxygen bond in its molecular structure endows it with low surface tension, which is easy to spread on the surface of foam and destroy foam.

Polyether defoamer: has high chemical stability and good compatibility, suitable for use in water-based varnishes with high transparency requirements. It eliminates foam through non-ionic mechanism, and has little impact on the system.

Mineral oil defoamer: Low cost, suitable for some cost sensitive application scenarios. However, it should be noted that it may have adverse effects on the glossiness and drying performance of the coating.

Polymer defoamer: it can effectively inhibit the formation of foam by the adsorption and bridging of polymer segments. This type of defoamer usually has good dispersibility and stability, and is suitable for various aqueous systems.

English

English

Chinese

Chinese Vietnamese

Vietnamese

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT