1825 has high defoaming efficiency without appearance of fish eyes and poor adhesion problem. It is suitable for water-based formulations and can remove stubborn foams. It has very good compatibility, and, it can be used in the formulations with a variety of leveling agents and wetting agents etc. It can be applied in strong acid and strong alkali aqueous systems. It is widely used in varnish and paint formulations. It is suitable in water-based pure acrylic emulsion, styrene-acrylic emulsion, vinyl and EVA emulsion, PU dispersion and those mixed systems, etc.

SHORT DESCRIPTION:

1825 is mainly composed of modified polysiloxane, it is a silicone defoamer with excellent performance, which has good defoaming, leveling and degassing effect.

FEATURES:

1825 has high defoaming efficiency without appearance of fish eyes and poor adhesion problem. It is suitable for water-based formulations and can remove stubborn foams. It has very good compatibility, and, it can be used in the formulations with a variety of leveling agents and wetting agents etc. It can be applied in strong acid and strong alkali aqueous systems. It is widely used in varnish and paint formulations. It is suitable in water-based pure acrylic emulsion, styrene-acrylic emulsion, vinyl and EVA emulsion, PU dispersion and those mixed systems, etc.

TYPICAL PROPERTIES:

|

Index |

Result |

|

Appearance |

Milk-white liquid |

|

Solid content |

25~30% |

|

Density |

1.01 |

|

pH value |

6.0~9.0 |

|

Viscosity(25°C) |

1000~3500mPa·s |

APPLICATIONS:

1825 is especially suitable for water-based industrial coating systems, architectural coatings, water-based inks, overprint varnishes, water-based wood, furniture coatings and parquet floor paints, water-based metallic paints, automotive paints, amino baking varnishes, transparent industrial paints, leather coatings, washing agents, etc.

APPLICATION PROCESS:

In order to fully disperse the defoamer, it is best to stir before use. It can be added in the let-down stage, pre-diluted or directly added to the paint as supplied. The long-term effectiveness of defoamers depends on the system and should be tested in different formulations (experiments at different temperatures are recommended). It can be added after the foam is generated or added to the product as an antifoam component.

Recommended dosage:

0.1-0.3% of the total amount. The above recommended levels can be used for orientation. Optimal levels are determined through a series of laboratory tests.

PACKAGE: 25KG/200KG plastic pail.

SHELF LIFE: Stored in a dry and cool place. The storage temperature is kept at 5℃~35℃. Shelf life is 12 months from the date of manufacture.

|

Antifoam Tego825 and our contrast sample 1825 in aqueous acrylic varnish |

one.experimental objective

Compare the performance of Tego825 and our contrast sample 1825 in aqueous acrylic varnish

- experimental result

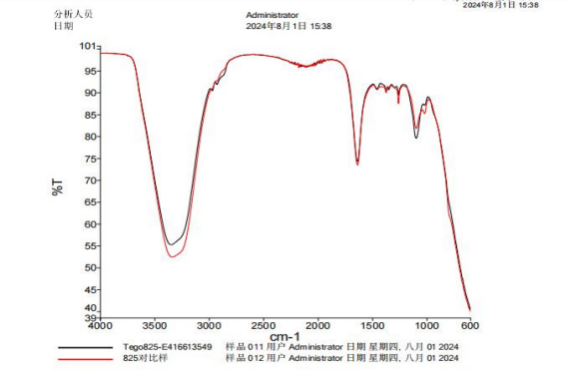

2.1 IR spectral comparison

|

Sample name |

best match |

relativity |

Whether through |

|

Tego825 |

825 It is compared with our company 1825 |

0.979367 |

yes |

2.2 Decoaming contrast

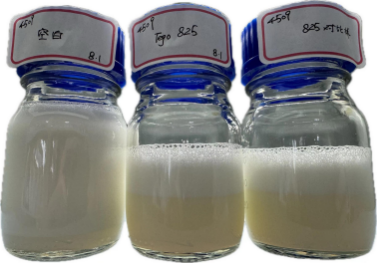

1. Starting state

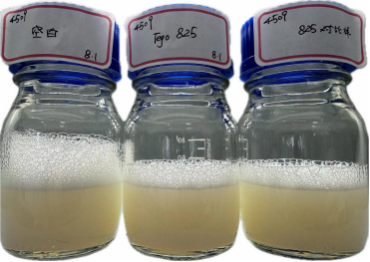

- Hold still for 1 hour

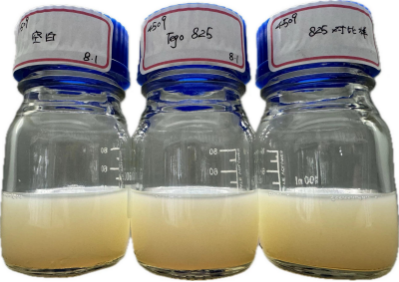

- After complete defoaming (photo taken the next day)

2.3 Scrmembrane contrast

- Experimental summary

|

Infrared correlation |

additive amount |

Bubble height |

Insulation time |

Scratch effect |

|

|

blank space |

- |

0 |

- |

- |

Small bubble |

|

Tego825 |

1 |

0.40% |

identical |

identical |

No bubble |

|

Contrast the sample |

0.979 |

0.40% |

No bubble |

||

Summary: Infrared spectrum shows that the correlation between our 1825 and Tego825 is 0.9793; oscillation foaming is highly consistent, static defoaming

After 1 hour, the foam is highly consistent; the membrane surface, which is a matching material.

English

English

Chinese

Chinese Vietnamese

Vietnamese

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT